- Home

- Our History

Portrait of Harold E. Williams

Harold E. Williams started with a dream 100 years ago. As an engineer with an entrepreneurial spirit, he founded the H.E. Williams Company in 1921. Renting a 25' x 50' room in Carthage, Missouri, H.E. made kitchen utensils, static signs, folding picnic tables and bicycle parts with the help of just one assistant. He would finish operations for the day and sell products door-to-door at night.

Original 1921 facility

Potato masher

Bicycle kick stand

Folding table

1920s The Automotive Years

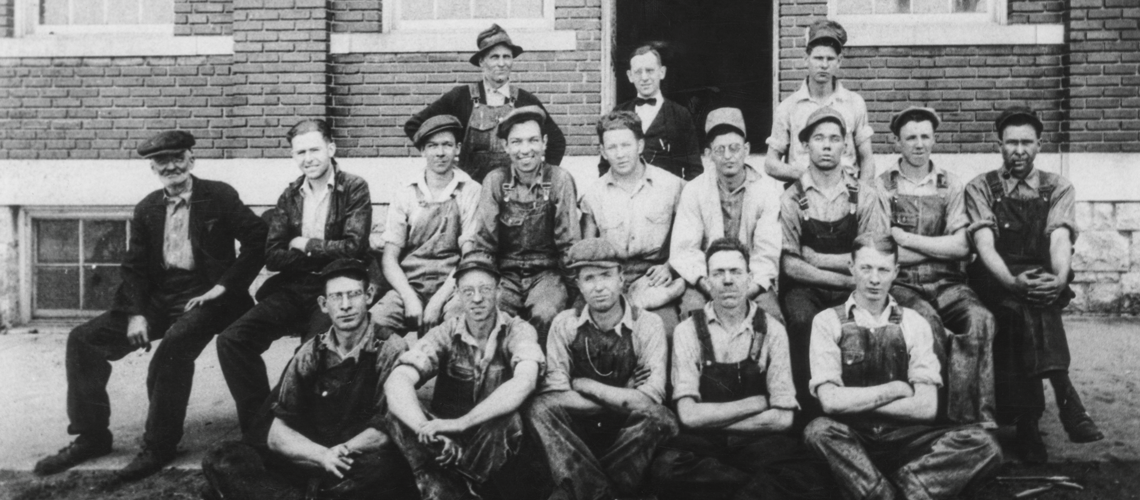

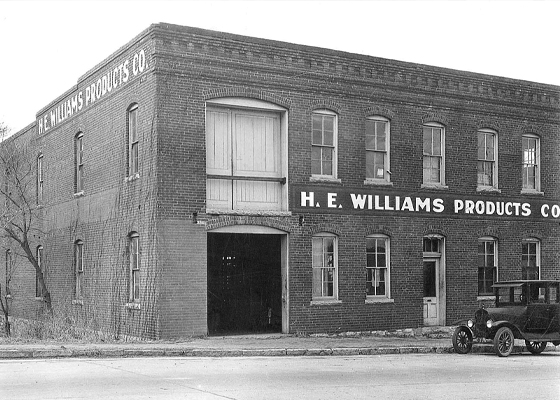

By the mid-1920s, the company made various gadgets for automobiles, including folding luggage racks, canopies for rumble seats, radiator bug screens, underslung creepers and seat cushions. Moving twice throughout the decade, H.E. settled the company into its location on Route 66 in 1929.

H.E. (bow tie) and his workforce

Patented folding luggage rack

Factory, circa 1924

Rumble seat canopy

Seat cushion

1930s Never-Ending Ideas

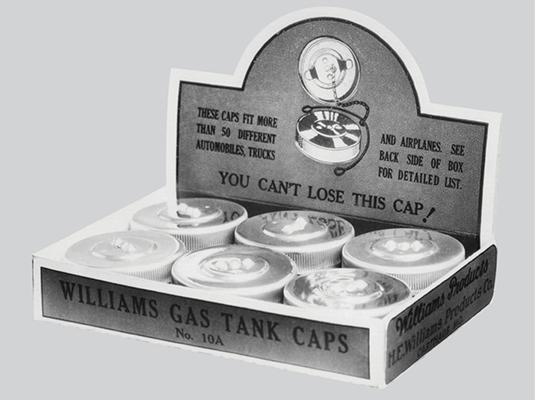

H.E. was awarded many different patents, not only for products, but also their production. By the 1930s, gas and radiator caps, sun visors and radio antennas were being produced.

In 1939, H.E. attended the World's Fair in New York City, where he witnessed the introduction of fluorescent lamps. He immediately started engineering fixtures to house the new light source. By December of that year he had ordered machinery to produce product.

1936 workforce

Patented airplane and automobile gas caps

Externally-mounted sun visor

Patented car antenna

Seat cushion assembly line

1940s First In Fluorescent

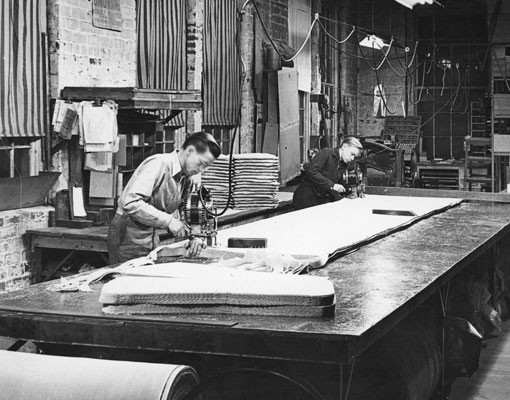

By the early 1940s, H.E. had engineered a suite of fluorescent fixtures and began exhibiting his products at industry trade shows. During World War II, Williams also made ammunition casings, cable pulleys, and bomb clips for American warbirds. By the late 1940s, lighting was at the forefront of the business, and the factory was expanded to double the square footage.

Fluorescent Futurama, 1941

1940s factory floor

The workforce, November 6, 1941

Factory on historic Route 66

Management meets with Department of Defense

1950s Engineering Excellence

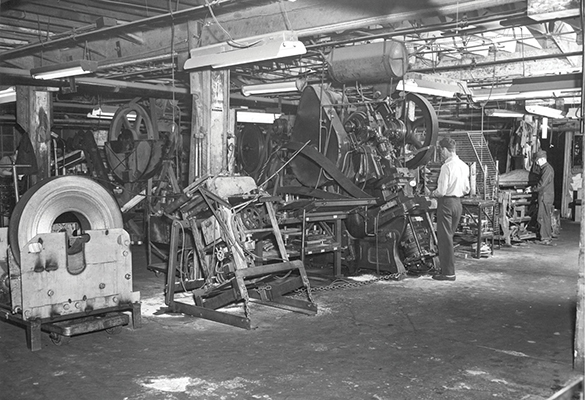

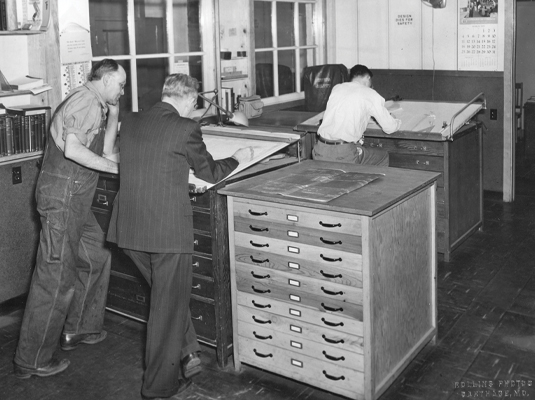

In the 1950s, H.E. developed a line of outlet and switch boxes featuring preset nails – an industry standard today. Not only did H.E. engineer the products, he designed the manufacturing equipment that would meet his production standards. During this time, John Williams, H.E.'s son, began to learn the lighting business under the direction of his father.

H.E. consults with draftsmen

Early Williams truck

Outlet box assembly line

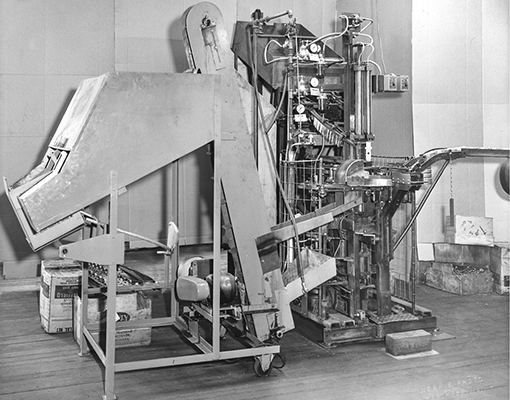

Nail crimping and outlet box machinery

1960s Room to Grow

During the 1960s, the company continued to introduce new products for educational facilities, retail shops, and commercial office spaces. With business booming, H.E. saw the need for additional manufacturing space and began moving operations to its current location on Fairview Avenue, where he installed the first conveyorized paint line. The move was accomplished without disrupting production.

Paint system installation

New fabrication area

Tool and die machinist

Management at 1965 tradeshow

1970s Lifelong Partnerships

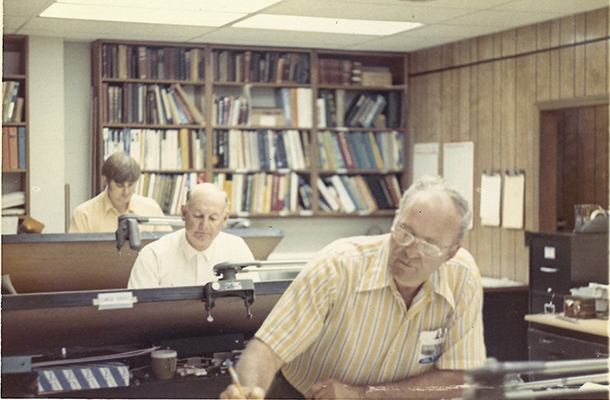

While H.E. continued to oversee operations, John focused on fostering sales relationships and expanded the business to a national level. During the 1970s, the company realized significant growth and introduced its first quick-ship stocking program.

Factory, mid 1970s

1973 assembly line

Coil-fed fabrication equipment

Drafting engineers, late 1970s

Management performs quality check

1980s A New Generation

John Williams, mid 1980s

John Williams became CEO in 1980. He raised the bar by focusing on product quality and customer service. A powder-coat paint system was installed, immediately setting Williams apart from the competition. In the late 80s into the early 90s, the company made acquisitions that substantially enhanced the product offering.

John’s son, Mark Williams, began his career at the lighting company working on the production floor. Mark furthered his knowledge of the business by spending several years in customer service and, eventually, moved on to lead the corporation’s marketing initiatives.

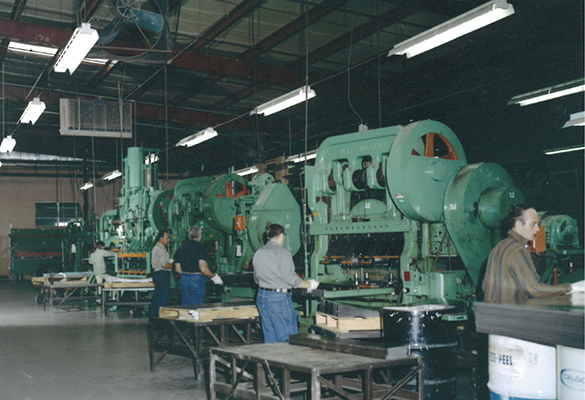

Arrival of high-speed production equipment

Fabrication, circa 1980s

1980s assembly line

Tool and die shop

1990s Three Generations Strong

Mark Williams, late 1990s

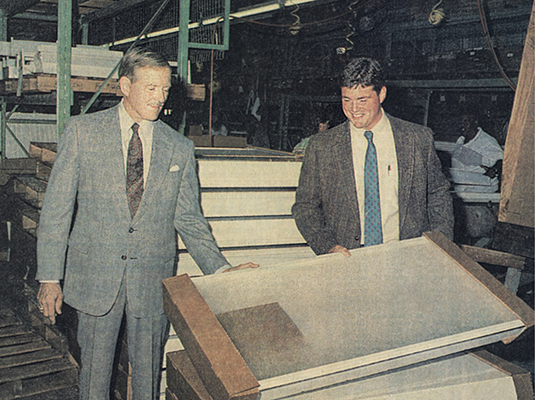

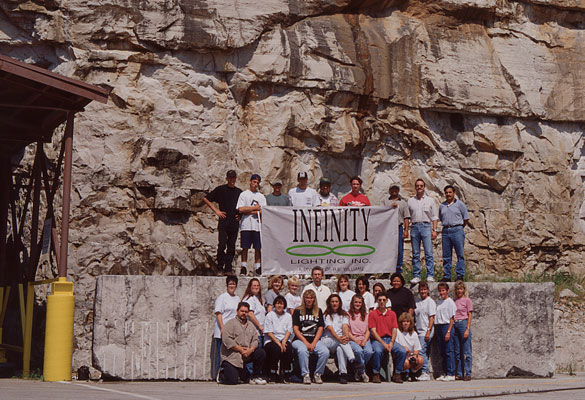

In the mid-1990s, Mark Williams became CEO starting the 3rd generation of Williams leadership. During this time, the first CNC machinery was purchased which enabled the company to grow the product line more quickly and to satisfy custom modification requests. Mark continued to modernize the business operations by prioritizing in-house production with lean manufacturing processes.

John and Mark Williams, early 1990s

Underground manufacturing facility

CNC fabrication, mid 1990s

Underground offices

Lightfair tradeshow, mid 1990s

Early CNC fabrication machine

2000s Bolstering Production

To meet increasing market demand, the facility underwent a massive upgrade in 2005 that resulted in over 300,000 square feet of conditioned production space. A first-class customer experience center, additional office area, new fabrication equipment, an enhanced powder-coat paint system, more assembly lines, and extra warehousing were included in the expansion. The Williams portfolio flourished with the acquisition of several niche lighting manufacturers.

Current Williams factory

Powder coat paint system

Assembly area

2010s An Industry Evolution

With the advancement of LED technology, lighting quickly evolved, prompting Williams to offer innovative designs around the new source, adapt production processes, and build out a portfolio to include a full suite of LED luminaires and controls solutions.

MX2 linear and 6DR downlights

MX4R linear and 6DS downlights

RND architectural rounds

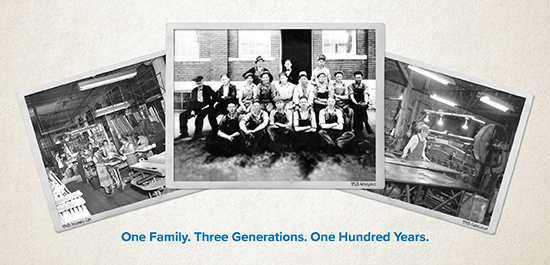

One Family. Three Generations. One Hundred Years.

Manufacturing to the exacting standards established in 1921 – with performance and quality in mind. Still made right here in Carthage, Missouri and still the best.